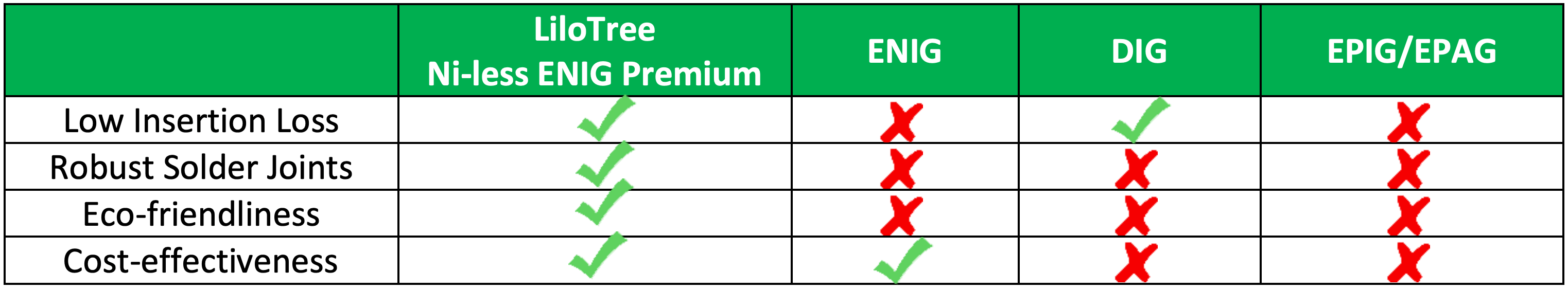

ENIG has been an industry standard for final finishes. However, with higher frequency and high end HDI, ENIG is no longer the best solution. Current ENIG has many issues that include corrosion / black pads, dendritic growth, high insertion loss, cyanide Au, harsh processing environment for solder mask, labor intensive bath monitoring and controlling and its expensive.

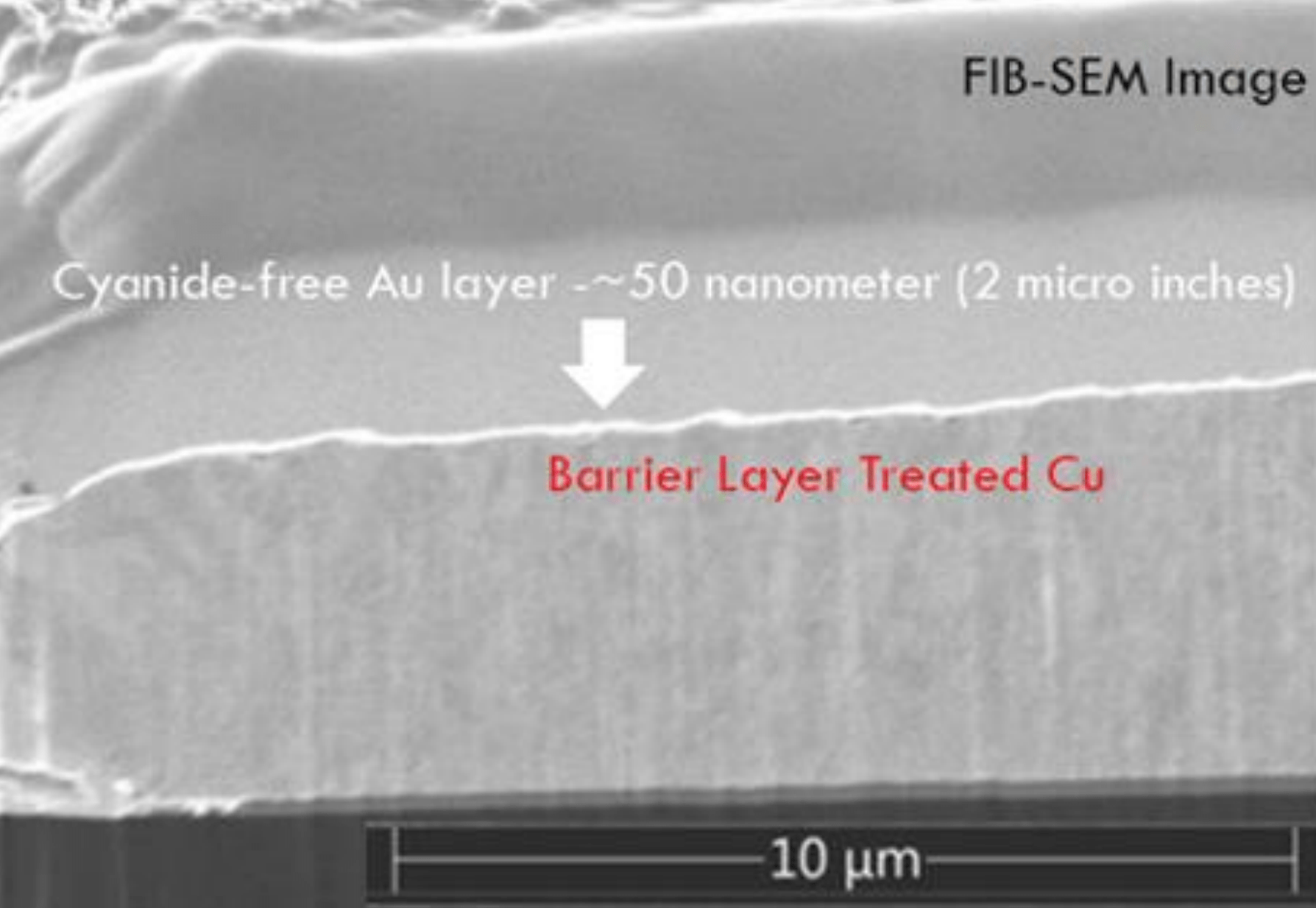

Taiyo America is pleased to introduce LiloTree’s solution for a true universal surface finish. This is a Ni-less ENIG-Premium final finish with optimum performance and better reliability. This is a solution for 5G-High Frequency-HDI-RF-MW PCBs/ICs. This final finish is completely Ni-free and the Au plating chemistry is free of all cyanide.

LiloTree’s Ni-less ENIG-Premium product has already been approved for these industries: