An Engineer's Perspective, July 2019

When I first entered the PCB industry, Photoimageable solder masks had already been introduced – not liquid photoimageable (LPI) solder masks but dry film solder masks (DFSM) and they were quickly becoming the choice for designs if registration was too tight for conventional screen print.

When I first entered the PCB industry, Photoimageable solder masks had already been introduced – not liquid photoimageable (LPI) solder masks but dry film solder masks (DFSM) and they were quickly becoming the choice for designs if registration was too tight for conventional screen print.

The rise in popularity of DFSM placed a greater demand on artwork generation and phototools. Diazo phototools were the norm, created by exposing through a silver halide original artwork, using a flip top exposure machine and then developed using an ammonia developing process, reproducing a working phototool that you could hand register to the panel. I remember one of the main rules of diazo was that you couldn’t over develop it, but you could certainly under develop diazo with the consequence being the ability to create lots of scrap during expose because the opaque areas would become less effective at blocking light. Oh, and we can’t forget the smell of those old ammonia diazo developers too.

As the complexity of PCB designs increased, so did the demands put upon diazo phototools. Temperature and humidity’s role on dimensional stability, mis-registration, repetitive defects and poor drawdown during exposure, were all daily challenges. When LPI solder masks came along, the issues were compounded by artwork sticking due to inadequate tack dry ovens and solvent attack on the emulsion, causing low D-max values and mask on pads.

As the complexity of PCB designs increased, so did the demands put upon diazo phototools. Temperature and humidity’s role on dimensional stability, mis-registration, repetitive defects and poor drawdown during exposure, were all daily challenges. When LPI solder masks came along, the issues were compounded by artwork sticking due to inadequate tack dry ovens and solvent attack on the emulsion, causing low D-max values and mask on pads.

Due to these headaches, plus many more, its no wonder LDI (Laser Direct Imaging) and now, DI (Direct Imaging) exposure equipment have become so popular in the industry. Exposing with digitized data files which eliminate phototools altogether, eliminate many of the common, day to day exposure headaches. Granted, LDI and DI exposing equipment each have their own variables and limitations, but overall are more versatile and capable exposure options.

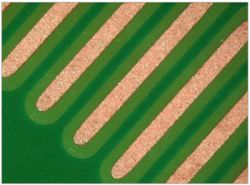

To optimize the advantages of the newer exposure equipment, Taiyo America offers many solder mask choices to help you take full advantage of the digital age. These include DI version of the industry’s most popular LPI solder masks as well as new LPI solder masks, designed from the ground up, to help bring out the full capabilities of direct imaging.

To optimize the advantages of the newer exposure equipment, Taiyo America offers many solder mask choices to help you take full advantage of the digital age. These include DI version of the industry’s most popular LPI solder masks as well as new LPI solder masks, designed from the ground up, to help bring out the full capabilities of direct imaging.