A major concern in today’s electronic’s component is the amount of heat generated due to miniaturization, higher layer counts, higher power requirements, and a massive increase in data transfer/processing. This is causing electronics to overheat at an exponential rate. The amount of internet connected devices worldwide is projected to reach over 75 billion by 2025, electric vehicle growth projected to reach up to 65 million by the year 2040, and consumer electronics such as smartphones, tablets, and TVs to skyrocket to over 300 million for 2025 production alone.The current solutions include copper heat piping, heat sinks, and fan coolers and are becoming too bulky.

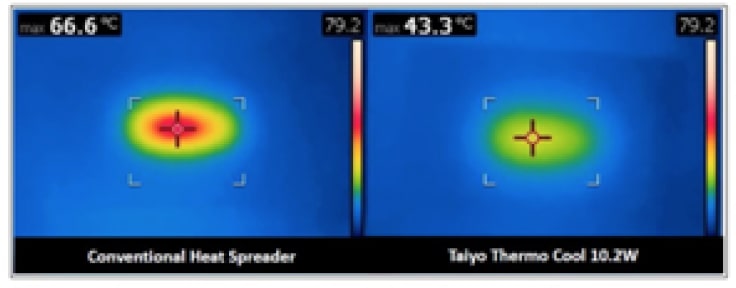

Because electronic devices continue to grow in the marketplace, shrink in size, and provide even more performance, Taiyo has created a Thermal Management Heat Dissipation ink called Thermo Cool 10.2W. This single component ink is thermally cured, halogen free, and silicon free.

Example an “IC package”

The term packaging derives from the placement of a smaller component (for example and IC (interconnect) circuit board being placed on top of the larger motherboard or “substrate.” The combination of the IC semiconductor and the substrate (motherboard) is called a “package.”

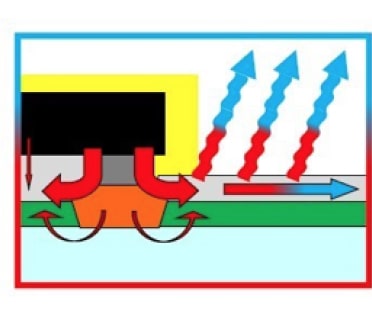

This IC circuit board acts as a processor that enhances the speed for data transfer throughout the board. In other words, the brains of the circuit board. Because there is so much data going through the IC, a large amount of energy is being generate. Therefore, a large amount of heat is being generated. The issue is with the IC packages is that they are thin, so this generated heat can distort them. To resolve this, Taiyo’s heat management solution, Thermo Cool, is placed in between the IC package and the circuit board to prevent overheating and work as the adhesive to the motherboard. Since the IC is traditionally mounted down on all four corners, using Thermo Cool as an adhesive to cover the entire board, this will prevent any warping of the IC.

In the diagram above, you will see that Thermo Cool is placed in between the IC circuit board (processor) and the main substrate (printed circuit board). The Thermo Cool ink then successfully dissipates the heat generated from the adhesion of the two board.

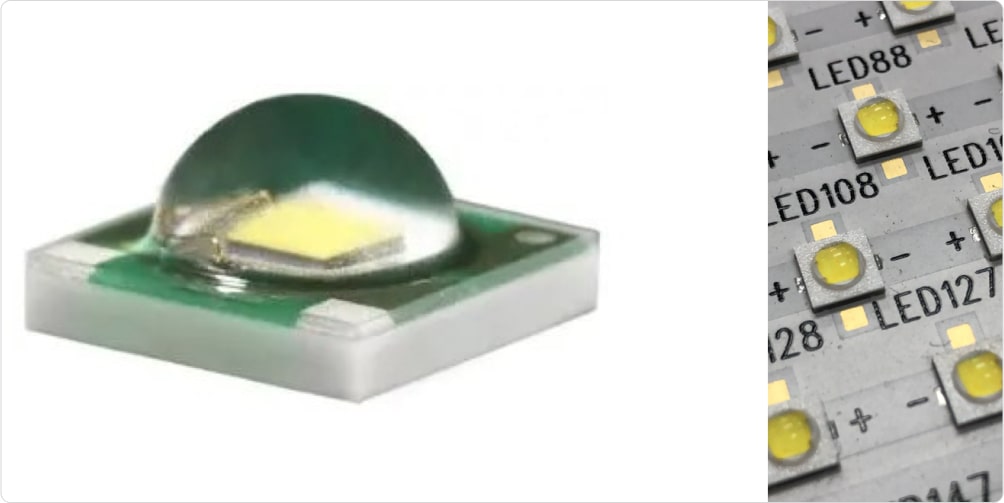

Light Emitting Diodes (or LEDs) gexnerate a massive amount of heat. Currently, during the LED adhesion process to the circuit board, there are Thermal Interface Materials (TIMs) that are used. These TIMs act as a “glue” for the LED to the printed circuit board and can only remove so much of the heat generated when the LED is active.

The images above show a single LED package (see diagram below for more information) and a multi LED circuit board with white ink.

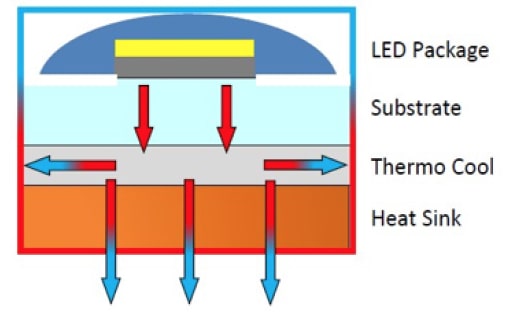

By using Taiyo’s Thermo Cool to adhere the LED to the printed circuit board, up to 10.2W/m K (Watts per meter Kelvin) amount of heat will be removed. In the diagram below, you will see the LED is placed on the substrate (printed circuit board). Thermo Cool is then placed on the reverse side of the substate before the adhesion of the heat sink (material used to pull heat out of circuit board)

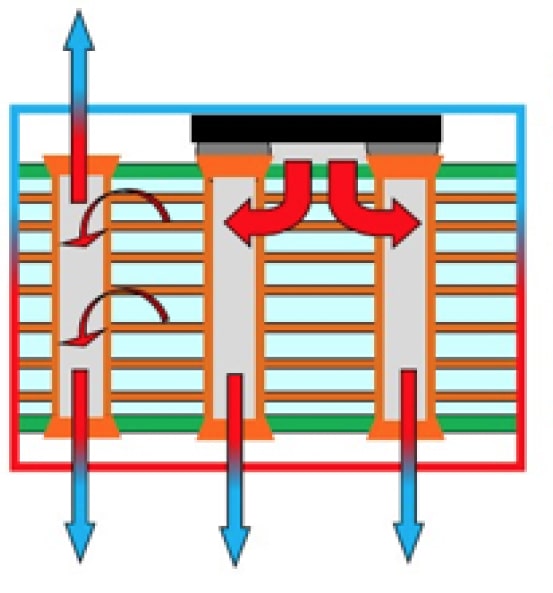

The Via Fill application is your hole filling solution for areas of the printed circuit board where holes are unwanted. When you have a multi-layer board and you drill a hole to connect two paths, the hole will need to be protected from contaminants getting in and interfering with the conductivity.

The more layers in your printed circuit board, the more holes that will be drilled. Meaning more copper. And when there is more copper, there will be more heat generated.

With Taiyo’s Thermo Cool, heat will be pulled out of the circuit board and increase its reliability and longevity.

The diagram below shows a typical high-layer printed circuit board and demonstrates how Taiyo’s Thermo Cool ink can pull the heat out of the substrate and increase its reliability.

- 100% solids

- Very low shrinkage

- Excellent adhesion to copper

- Plateable

- High Tg

- Low CTE

The diagram show a typical high-layer printed circuit board and demonstrates how Taiyo’s Thermo Cool 10.2 ink can pull heat out of the substrate and increase its reliability.

NEXT STEP